I originally wrote code for the MS5541C pressure sensor using bit banging, and described the result of my investigation in the previous log entry. At the end I mentioned that the sensor’s weird digital interface is kind of like SPI, and looks SPI-compatible, with several differences that could be worked around. The most notable difference was that reading and writing data happen out of phase with respect to the serial clock edge. It wound up being a little squirrellier than that, but it worked out. Below is some code for accessing the MS5541C with SPI. It runs on a Seeeduino Mega (which is compatible with the Arduino Mega and uses the ATmega1280 microcontroller), but I’ve eschewed the Arduino libraries for the sake of more control (and, for the ol’ bit-banging, better timing resolution). Some of the code, particularly the SPI stuff, could be replaced with Arduino library calls.

Continue reading

Tag Archives: nested parentheses

Interfacing AVR/Arduino with the MS5541C pressure sensor

The MS5541C is kind of an oddball sensor, BUUUUUUUT it’s small, it can be used underwater (with appropriate waterproofing), it’s cheapish (~$30), and Digikey sells it. It’s a pain to get running though, because of its hardware interface (50 mil pitch, surface mount (and not the good kind of surface mount either)) and its data interface (which doesn’t implement any particular standard protocol).

I tried carving out an interface board using some copper-clad PCB and a rotary tool, but I didn’t do a good job and it was really hard to get the 50 mil pads to line up with the messily-carved copper traces. I used a heat gun to solder the sensor onto the PCB, and it almost worked—but two of the pins were shorted. And of course a copper pad got torn off of the sensor when I tried to remove it from the PCB. I bought another one and connected it to a 100 mil header via some ribbon cable. That’s the wrong thing to do. The datasheet specifies that the sensor should be securely fastened to a circuit board to prevent it from flexing, although it hints that might be just to prevent stress on the solder pads (which are, as previously noted, not incredibly strong) and not necessary to improve sensor performance. The spec also says that a 47 μF tantalum decoupling capacitor should be placed as closely as possible to the sensor. That is a noise reduction requirement, but whatever, there’s one on the Arduino that I have the sensor hooked up to and that’s good enough for now. In any case, eucatastrophically, it works.

The data interface is a little easier to work out. Like I said before, it doesn’t use a standard protocol, presumably to keep the internal circuitry as uncomplicated (and small and low-power) as possible. The thankfully decent datasheet defines the protocol using electrical timing diagrams, and fortunately it’s simple enough once you work through it:

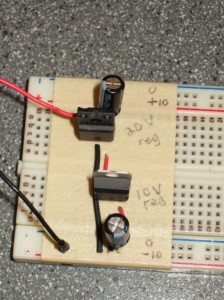

How I’m powering my acoustic modem

I’ve covered how not to power an acoustic modem, and how I’d like to power an acoustic modem, now it’s time to tell how I’m doing it right now.

To restate and clarify the problem: I want to use an acoustic transducer to transmit and receive data via pressure waves. The transducer I have transmits a 40 kHz carrier wave, and can be driven by up to 20 V. That means that when transmitting, the circuit must alternate a 20 V signal back and forth between the transducer’s two input pins, once every 25 microseconds. Additionally when receiving, the transducer’s output signal needs to be amplified into a usable signal. Continue reading

How to power an acoustic modem

I mentioned before that I’m basing my acoustic transducer off the Devantech SRF04 ultrasonic ranger. I’m removing the piezoelectric transducers from a dead SRF04 unit and using them for my modem. The transducers, which are the part that generate and receive the acoustic pressure wave that carries data, have a range of about 6 metres or so (one way), are driven with up to 20 V, and resonate at around 40 kHz.

The puzzle I’m working on right now is how best to actuate the transducer to generate a 40 kHz pulse. The SRF04 does it using a chip that’s intended to convert 5 V logic signals into the ±12 V signals used for the RS-232 serial protocol. Unfortunately most RS-232 converter chips aren’t made to power an acoustic transducer, and they aren’t able to provide enough current to generate a strong signal.