The MS5541C is kind of an oddball sensor, BUUUUUUUT it’s small, it can be used underwater (with appropriate waterproofing), it’s cheapish (~$30), and Digikey sells it. It’s a pain to get running though, because of its hardware interface (50 mil pitch, surface mount (and not the good kind of surface mount either)) and its data interface (which doesn’t implement any particular standard protocol).

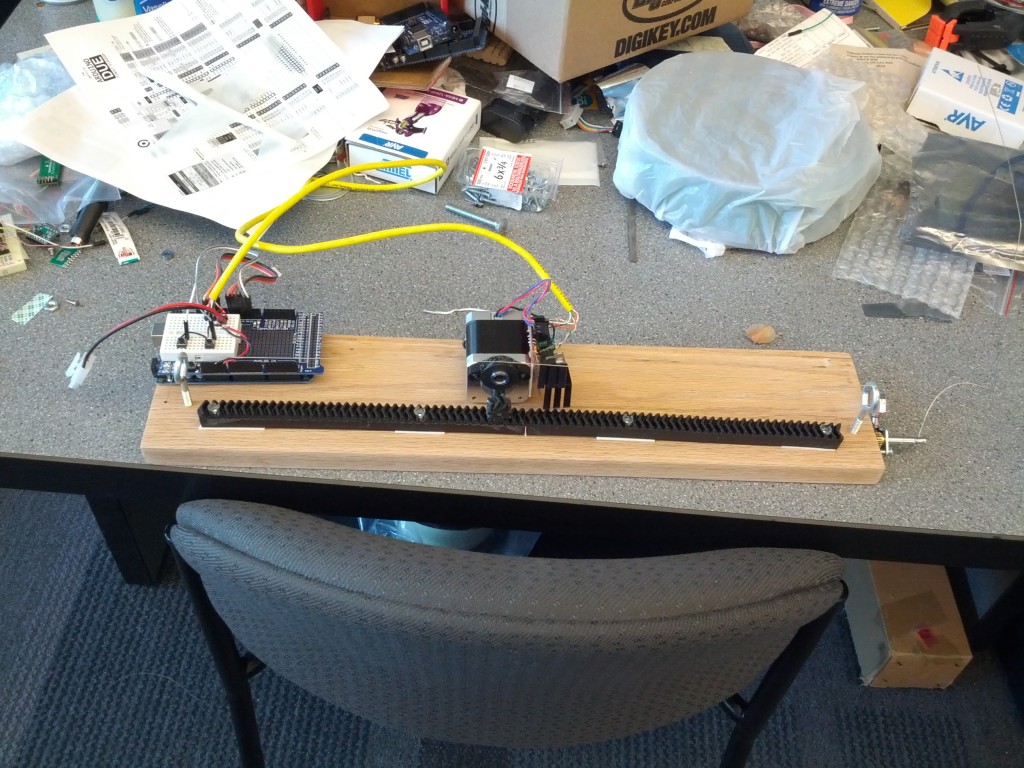

I tried carving out an interface board using some copper-clad PCB and a rotary tool, but I didn’t do a good job and it was really hard to get the 50 mil pads to line up with the messily-carved copper traces. I used a heat gun to solder the sensor onto the PCB, and it almost worked—but two of the pins were shorted. And of course a copper pad got torn off of the sensor when I tried to remove it from the PCB. I bought another one and connected it to a 100 mil header via some ribbon cable. That’s the wrong thing to do. The datasheet specifies that the sensor should be securely fastened to a circuit board to prevent it from flexing, although it hints that might be just to prevent stress on the solder pads (which are, as previously noted, not incredibly strong) and not necessary to improve sensor performance. The spec also says that a 47 μF tantalum decoupling capacitor should be placed as closely as possible to the sensor. That is a noise reduction requirement, but whatever, there’s one on the Arduino that I have the sensor hooked up to and that’s good enough for now. In any case, eucatastrophically, it works.

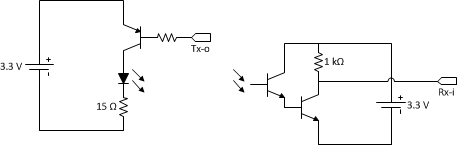

The data interface is a little easier to work out. Like I said before, it doesn’t use a standard protocol, presumably to keep the internal circuitry as uncomplicated (and small and low-power) as possible. The thankfully decent datasheet defines the protocol using electrical timing diagrams, and fortunately it’s simple enough once you work through it:

Continue reading →