It’s pretty hard to get a watertight object out of our Makerbot Thing-O-Matic. The walls of printed objects are pretty solid, but unexpectedly porous; even a thick block printed with 100% infill will allow water to penetrate it due to errors around the edges and imperfectly fused strands of plastic. If you want to make a hollow object waterproof you’re going to have to do some post-processing.

It gets worse when the object is a curved surface, as is my AUV hull. I’ve read that objects can be made watertight by adding outer shells. That may be true for some objects, but on objects that curve along the z-axis the number of shells exposed to the surface grows as the tangent plane gets closer to parallel to the printer’s build platform—and big holes start to form.

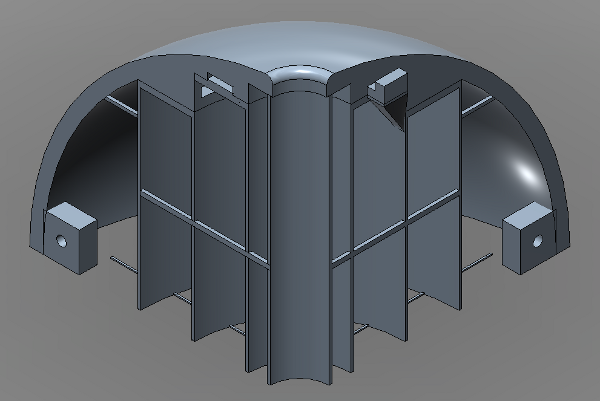

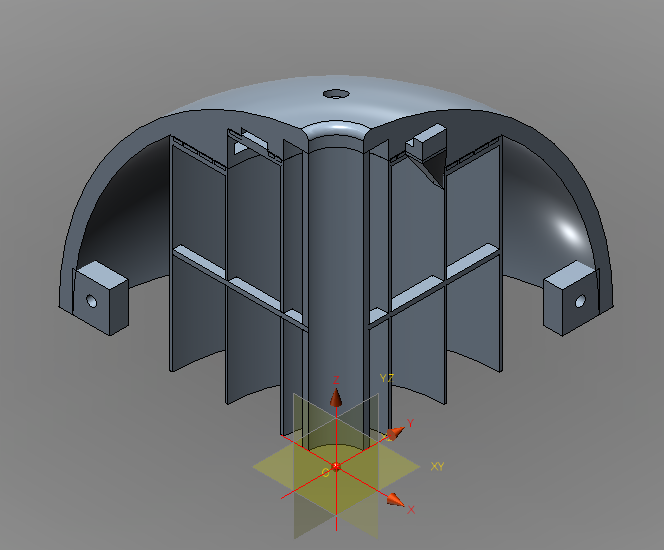

My hull doesn’t actually have to be watertight, it’s a wet hull. But it has to be airtight in order to hold the bubble of gas that controls the robot’s buoyancy. Here’s what the airtight hull looks like: