I did a bit of testing on my AUV hull design, and finally got a prototype ready to go. I’ve been working on the design for several months in Autodesk 123d, which is a pretty great program if you can put up with the crashes, corrupt save files, and slowness (hey, it’s beta).

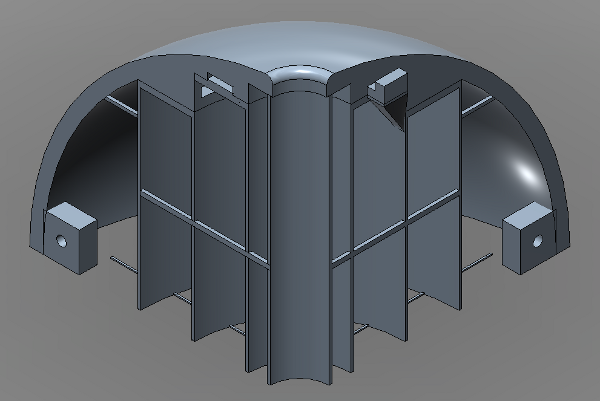

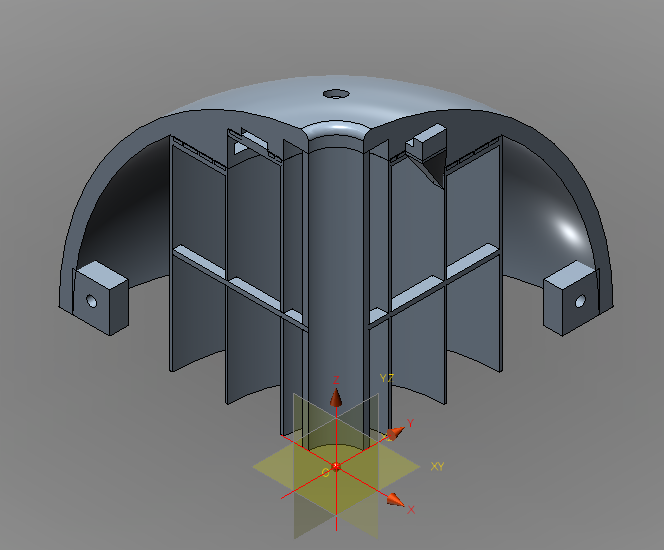

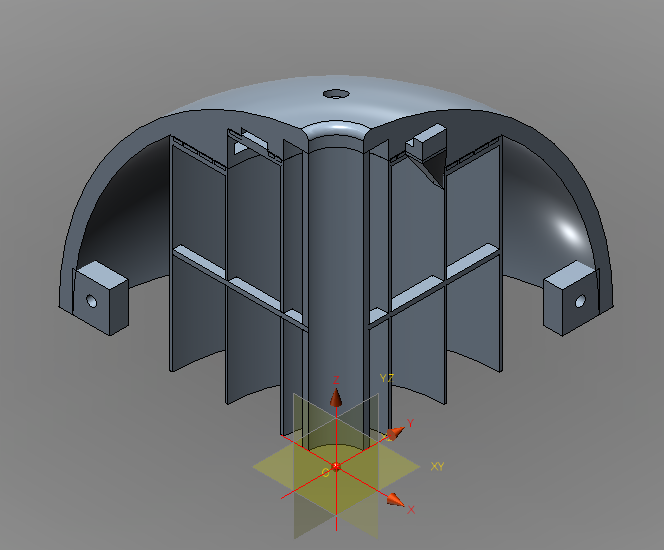

Here is my current design in full, including the support structures:

The 3D model for my spherical AUV hull.

This is one eighth of the hull; I call it a semidemihemisphere. Eight of these will make a sphere 18 cm in diameter. I split it up into eighths because I’m using a Makerbot 3D printer and its build platform is limited to a cube about 10 cm to a side. Also, this way each piece can be identical (or nearly so).

One limitation in the Makerbot is that it can’t print overhangs very well, so I had to add some support structures that can be cut away. In this entry I will ignore that and focus on the hull design:

Continue reading →